We discussed containment buildings in a previous post where we detailed what they are and how they came to be. Today we’re going to take a closer look at how containment buildings must be designed and what measures are taken to ensure protection of human health and the environment.

When the EPA wrote the standards for containment buildings they modeled them closely after those for hazardous waste tanks. Because the standards are so important to the protection of human health and the environment they are primarily regulations concerning structural soundness and measures that must be set to prevent wastes in the buildings from leaking and getting into the environment. In order to ensure these regulations and measures are met, a professional engineer must inspect and certify a containment building before it can be used.

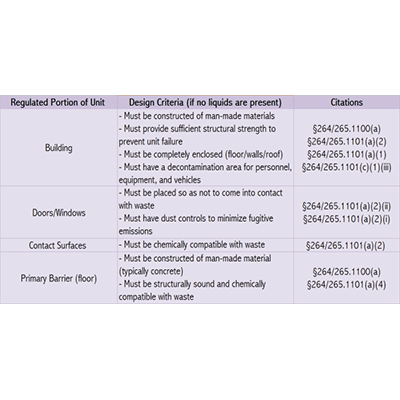

Section 24/265.1101(a) details design standards that containment buildings must meet. These standards include needing to be fully enclosed with a floor, walls and a roof constructed of manmade materials which have, “sufficient structural strength to withstand movement of wastes, personnel, and heavy equipment within the unit.” Doors and windows don’t need to meet the standards but the building must be designed in such a way that wastes will never come in contact with them.

Controlling dust emissions is another key point. According to the EPA, “dust control devices, such as air-lock doors or negative air pressure systems (which pull air into the containment building), must be used as necessary to prevent fugitive dust from escaping through these building exits.”

Additionally, much like wastes must be compatible with their containers, surfaces that come in contact with the wastes being stored in the containment building must be chemically compatible with the wastes.

“The remaining containment building design standards establish a system of barriers between hazardous wastes in the unit and the surrounding environment. The floor of the containment building is considered the unit’s primary barrier, since it is the first measure used to prevent wastes from being released into the ground beneath the building. Construction materials vary with the type of wastes to be managed in the containment building, but concrete floors are typical.”

The table below details the standards required for containment buildings which manage no liquids. Keep checking our blog for more details about containment buildings housing liquid wastes.

All information for this blog post was gathered from the EPA document, “Introduction to Containment Buildings.” As always, this blog post is not intended to be comprehensive and it is always best to check with the EPA and local government for full, up-to-date, rules and regulations.

More News From Heritage

-

10/14/24

Heritage Environmental Services Announces Timothy Thomas as Chief Operating Officer

Heritage Environmental Services (“HES”), an EQT Infrastructure portfolio company, announced today that Timothy Thomas will join the organization as Ch

-

10/1/24

Heritage Environmental Services Complete Acquisition of EBV from General Dynamics

Heritage Environmental Services, an EQT Infrastructure portfolio company, has completed the acquisition of EBV from General Dynamics.

-

7/31/24

PFAS Regulations: Is 6 the Magic Number?

Learn more about the current and proposed regulation for PFAS and what they mean from our Chief Sustainability and Innovation Officer, Angie Martin.

-

6/27/24

Heritage Environmental Services to Acquire EBV from General Dynamics

Heritage Environmental Servicess, an EQT Infrastructure portfolio company, will acquire EBV from General Dynamics

-

6/13/24

Meet The Facilities – East Liverpool

An inside look at our incineration facility located in East Liverpool, OH

-

5/24/24

Habitat for Humanity 2024

Heritage hosted our 14th annual Habitat for Humanity build this month, partnering with over 50 employees from various THG companies.

-

5/6/24

Date set for the household hazardous waste collection in East Liverpool, Ohio

-

3/12/24

Equal Pay Day – Spotlighting Our Female Drivers